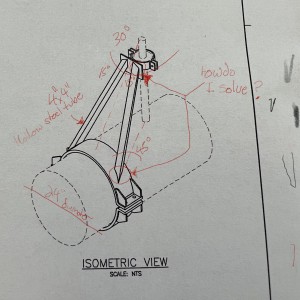

Three dimensional trigonometry problem

Hello. I am a pipe fitter and would like some help learning how I would calculate plotting ordinances on the steel tube to cut and fit to the contour of the pipe and the steel plate.

House2001

House2001

12

Answer

Answers can only be viewed under the following conditions:

- The questioner was satisfied with and accepted the answer, or

- The answer was evaluated as being 100% correct by the judge.

1 Attachment

574

The answer is accepted.

Join Matchmaticians Affiliate Marketing

Program to earn up to a 50% commission on every question that your affiliated users ask or answer.

- answered

- 1365 views

- $80.00

Related Questions

- Help deriving an equation from geometry and vectors

- Find the derivative of the function $f(x)=\sqrt{\sin^2x+e^x+1}$

- Trigonometry problem - A bee collecting nectar from flowers

- Integral of $\arctan x$

- Calculate the antiderivative of trigonometric functions

- Trigonometry sin cot CAST

- Find $\lim_{x\rightarrow \infty} \frac{1}{x^2}\sin x^2\tan x$

- Solve the Spherical Triangle

Could you please clarify what you are trying to calculate? It is a little unclear.

Hi Philip. Sorry, I’ll try to clarify. Let’s say I drew a line around the square tube 200mm from the end and then draw 16 lines down from that line to the end.( 4 lines per side running parallel with the square steel tube.) With the given angles what would the difference in length of the lines be to make contact with the pipe. And same scenario at the top but making contact with the 90° steel plate.

Lines 25mm apart

4 per side?! There are two side to the tube! I suggest you to draw a good picture and show all of what you tried to explain in the picture.

It may also help if you let me know what the main goal is here.

I agree, the description of the problem is confusing.

Also some important information is missing. What is the length of the vertical rod?

If I understand it correctly, you would like to know where you need to cut the square tube so that it perfectly fits the rube and the flat plate at the top? If so, this is indeed a very challenging problem and requires delicate computations. I could do it if you extend your deadline for at least another day.

Also what kind of mathematical background do you have? The answer to this question is not going to be very simple.

Hi savionF, yes that is what I’m looking for. I’ve extended the deadline ,thank you.

What is the length of the square tube? What is the angle that the square tube makes with the vertical line? If you don't know the answer to these questions the problems can not be solved.

If can explain the process of calculating the end point, if you can carry out some basic calculations on your own. Can you? It is impossible to provide a clean simple formula.

I use simple trigonometry everyday, to build piping systems I need to solve right and scalene triangles , but just easy two dimensional soh- cah-toa . I am definitely not anywhere near a mathematician , but I would appreciate any information and I’ll probably have to use google to begin to make sense of it. Thank you.

The tube is 2000mm long. The square tube slopes 45 degrees from the vertical line and tilts 15 degrees

Where is square tube ?

The two inclined rods are square tubes ?

I spent several hours on this. I have the right ideas but going through all the calculations is frustrating. I would say the bounty is low for the level of effort required to write a solution for this.

Hello savionF . Sorry for the trouble. I only have 20 dollars left in the account. I’d be happy to pay you for the work you’ve done if it brings me closer. In the real world application the diameter of the pipe , the angles and size and length of the square steel are always different. To build. I tape a string line to the desired center of the two points, and from that center I use 4 more string lines to maintain the actual dimensions of the square tube and physically measure the 4 points.

This only gets you so close, and I end up taking it down with a crane several times and grinding until the cope on the pipe works.